Inductive sensors crucial for Fei’s TEM electron microscope

The Eindhoven-based firm has actually been relying Sentech’s knowledge of sensors for around 15 years. In fact, Thermo Fisher is one of the reasons that Sentech was founded in the first place. Sensor technology developed by Sentech both ensures that the electron beam is aimed exactly at a specimen, and that the specimen is placed in the correct zero position.

It therefore appears just a matter of time until a combination of the nanotechnology developed by Thermo Fisher in Eindhoven and Sentech’s sensor technology becomes responsible for the next scientific breakthrough.

Scientific research at nanometer level

The very foundation of Sentech is closely linked to Thermo Fisher, previously known as Fei. Fei is the global market leader in the field of Life Science electron microscopy. Thermo Fisher develops and manufactures high-quality technology for scientific research and diagnostics.

Fei complements this range of technology in providing microscopy for nanometer and even picometer examination. Fei produces the most highly advanced and extremely powerful electron microscopes for microscopic examination on the most minute of scales. Its TEM (transmission electron microscope) and SEM (scanning electron microscope) enable the examination of specimens down to sub-nanometer level.

This scale was barely imaginable before. The instruments render individual atoms and molecules visible. Things that were previously invisible to humankind are therefore now available in high resolution. Fei’s electron microscopes literally defy the outer limits of our universe.

It is therefore hardly surprising that pioneering scientific breakthroughs are being made using Fei microscopes. In fact, scientific journal Nature even designated cryo-electron microscopy (cryo-EM) – a method of microscopy that can only be carried out using Fei microscopes (Titan Krios™) – Method of the Year 2015.

For the first time ever, scientists are now able to examine protein structures (RNA and DNA) right down to molecular and atomic level. University researchers and pharmacists expect to be able to develop new drugs and methods to treat diseases.

What’s more, Fei microscopes are also proving vital in the field of semiconductor research and the examination of minerals, industrial research and other research carried out at nanometer level.

Sentech sensors crucial to TEM electron microscope

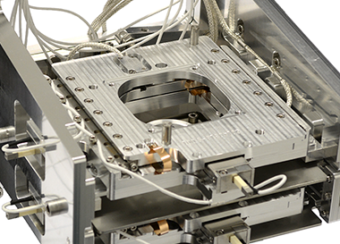

The Titan Krios™ TEM is a three-meter-high piece of equipment, which is assembled in Eindhoven using components sourced from various suppliers. It sends a beam of electrons down through a column comprising electronic ‘lenses’, onto the specimen.

The material to be examined is placed on the device’s four-spindled stage (CompuStage). Some of the electrons are absorbed by the material. Those which pass by it, however, form a sort of ‘slide image’ of the specimen in the image acquisition and detection unit. Software then converts the resulting data into two and/or three dimensional high-resolution images of the material.

The TEM comprises several main components, which are meticulously integrated in the assembly. In order to acquire a perfectly clear image of a protein structure or the surface of a semiconductor, it is absolutely vital that the CompuStage places the specimen in the correct position beneath the electron beam.

For the past 15 years, sensor technology provided by Sentech has vouched for both the stability and accurate positioning of this stage. And this also applies to the control of the aperture mechanisms, which guide the electron beam exactly onto the specimen. Back then, Sentech acted swiftly to plug the sensor gap left behind by Honeywell, which had just sold off its sensor production plant.

Sentech developed two types of sensor assemblies for the TEM models in question. Depending on their application, the inductive sensors perform either the stage homing (guiding it to the starting point) or detection.

The proximity sensor indicates whether the stage is in the vacuum space. This sensor prevents the space from being left open while a vacuum is created. The microscope comprises several aperture mechanisms. These position the aperture in the electron beam.

Sentech supplies sensor assemblies comprising inductive sensors to first-tier suppliers, including Frencken, which manufactures and supplies the aperture mechanism.

Partnership – improvements in close cooperation

Sentech cooperates closely with both Thermo Fisher’s operation engineers in Eindhoven, and with Frencken, the supplier of the aperture mechanism. Sean Ram, Account Manager at Sentech, explains the partnership: “The development of the TEM has been very much an ongoing process throughout the past fifteen years, particularly in the area of imaging. There have been colossal improvements in both the cameras and images. We have had to make various modifications to the sensor assemblies, due to both product changes at Thermo Fisher and advancing sensor technology developments.”

Sentech does not view herself as a sensor supplier, but rather a sensor integrator that thinks along with its customers. “We basically feel like an R&D extension of Thermo Fisher. Thermo Fisher can rest assured that its own stringent standards come as second nature to us at Sentech. For instance, the integrated circuit (IC) in certain sensors was recently replaced, as the previous one had become outdated.”

Professional supply chain vouches for high quality

Sentech carries out just-in-time delivery of its sensor assemblies (including wiring). Mr. Ram: “Sentech applies an extremely high quality standard, which we have embedded throughout the chain, from development up to distribution. This is the only means of complying with the high quality standards high-tech customers such as Thermo Fisher.”

The entire workforce has become quality minded. “And this also implies that we deliver sensor assemblies exactly where and when they are needed in the production and assembly process: just in time, to Thermo Fisher too. We simply cannot afford to make any mistake. The entire supply chain is highly advanced and ideally set, including a cleanroom with manufacturing, testing and packaging facilities.”

Optimize your machine with sensor integration

It is just a matter of time until a combination of the nanotechnology developed by Thermo Fisher in Eindhoven and Sentech’s sensor technology becomes responsible for the next scientific breakthrough. Big data is essential to make your machine more intelligent.

Based on customer needs and the perspective of the future, you determine which data you need. Moreover, you need the right sensor solution to collect big data.

What can you expect from technologies? Be inspired by our free e-book.